Leverage the New Issues Feature for Enhanced Tracking and Reporting of Issues

![]()

Check out the guide below or download it as a pdf: ![]()

Table of Contents

0:00 - Intro

0:10 - 2 main steps for tracking issues

0:29 - Track Issue Cost and Revenue in the Area Module with "Issue" line items

0:32 - Adjust the drawing if necessary

0:52 - Adjust line items

1:18 - Ensure accuracy of inventory items

2:00 - Ensure accuracy of cost and revenue for "Issue" line items

3:14 - Tracking issues that do not require a new top or remake

3:30 - Sink example

4:20 - Trip charge example

4:46 - Complete the "Issue" action and issue reason window

5:20 - (for setup) Ensure any additional follow up actions are added to the process

Issues by Category and Reason Report

This video describes the "Issues by Category and Reason" report which provides ActionFlow users with a comprehensive view of their callback, service claim, and remake activity. By analyzing and planning based on this report, fabrication shops can begin to address the underlying causes and reduce the time and money spent on issues.

Table of Contents

0:00 - Intro

0:08 - Getting Started

0:16 - Report Totals

0:40 - Revenue, Cos,t and Margin for Non-Material and Material Issue Line Items

1:01 - Category Totals

1:18 - Job and Issue Information

1:26 - Missed Deadline Issues

1:48 - Job Details - Breaking out cost and revenue for each issue line item

3:01 - Issues with a Category or Reason

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Setup

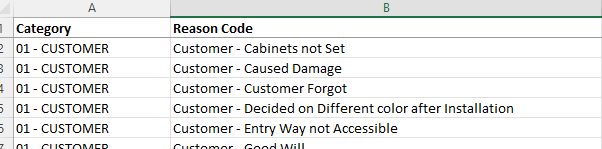

Step 4: Identify reasons issues occur

Your fabrication shop has a unique way of classifying and tracking issues which can be configured in ActionFlow.

Here are some examples of the reasons you may include.

For more examples, download the entire list by clicking the document: ![]()

Setup

Step 5: Consider if the job process needs additional follow-up actions in response to issue actions.

![]()

We highly recommend working with your account manager to set up this tool so please reach out if you are interested!

Administrators: To learn how to set this feature up,